Rotary Screw Air Compressor Guide

Air compressors are pneumatic devices that increase the pressure of a gas by compressing it into a smaller volume. The kinetic energy contained in the pressurized air can then be used to power various tools and equipment. Based on their method of operation, air compressors can be split into several categories. The most common types include:

- Rotary screw

- Rotary vane

- Scroll

What Is a Rotary Screw Air Compressor?

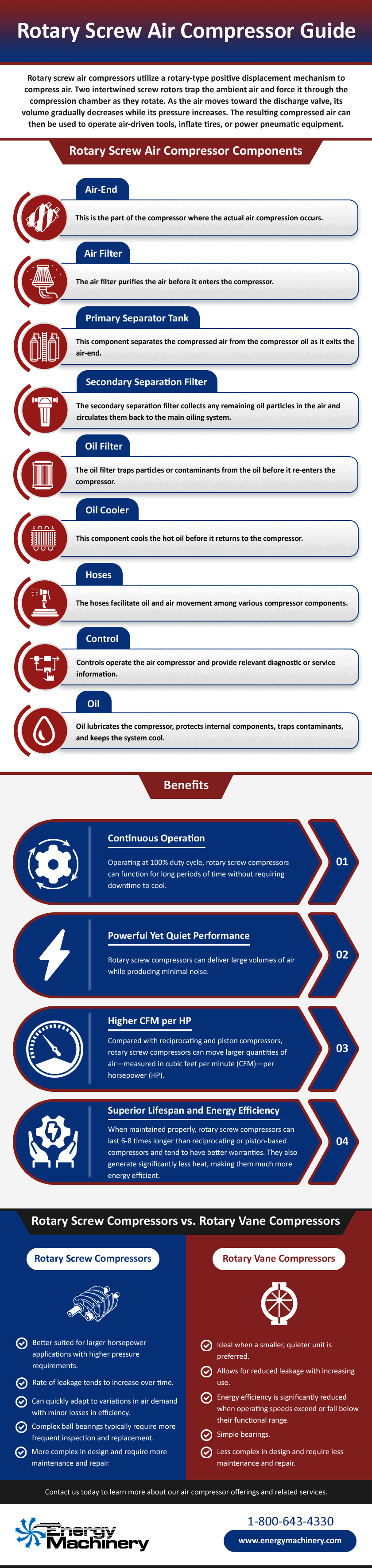

Rotary screw air compressors utilize a rotary-type positive displacement mechanism to compress air. Two intertwined screw rotors trap the ambient air and force it through the compression chamber as they rotate. As the air moves toward the discharge valve, its volume gradually decreases while its pressure increases. The resulting compressed air can then be used to operate air-driven tools, inflate tires, or power pneumatic equipment.

The main components of a rotary screw compressor include:

- Air-end. This is the part of the compressor where the actual air compression occurs.

- Air filter. The air filter purifies the air before it enters the compressor.

- Primary separator tank. This component separates the compressed air from the compressor oil as it exits the air-end.

- Secondary separation filter. The secondary separation filter collects any remaining oil particles in the air and circulates them back to the main oiling system.

- Oil filter. The oil filter traps particles or contaminants from the oil before it re-enters the compressor

- Oil cooler. This component cools the hot oil before it returns to the compressor.

- Hoses. The hoses facilitate oil and air movement among various compressor components.

- Controls. Controls operate the air compressor and provide relevant diagnostic or service information.

- Oil. Oil lubricates the compressor, protects internal components, traps contaminants, and keeps the system cool.

Rotary Screw Air Compressor Benefits

Rotary screw air compressors provide the following advantages in compressed air applications:

- Continuous operation. Operating at 100% duty cycle, rotary screw compressors can function for long periods of time without requiring downtime to cool.

- Powerful yet quiet performance. Rotary screw compressors can deliver large volumes of air while producing minimal noise.

- Higher CFM per HP. Compared with reciprocating and piston compressors, rotary screw compressors can move larger quantities of air—measured in cubic feet per minute (CFM)—per horsepower (HP).

- Superior lifespan and energy efficiency. When maintained properly, rotary screw compressors can last 6-8 times longer than reciprocating or piston-based compressors and tend to have better warranties. They also generate significantly less heat, making them much more energy efficient.

Rotary Screw Compressors Vs. Rotary Vane Compressors

While they offer similar benefits, rotary screw and rotary vane compressors each have distinct capabilities that influence their suitability for certain applications. These include:

- Applications. Rotary vane compressors are ideal when a smaller, quieter unit is preferred, while rotary screw compressors are better suited for larger horsepower applications with higher pressure requirements.

- Leakage & lubrication. While the rate of leakage in rotary screw compressors tends to increase over time, a rotary vane compressor’s design allows for reduced leakage with increasing use.

- Speed control. The energy efficiency of a rotary vane compressor is significantly reduced when operating speeds exceed or fall below their functional range. In contrast, rotary screw compressors can quickly adapt to variations in air demand with minor losses in efficiency.

- Bearings. Compared with the simple bearings used in rotary vane compressors, the complex ball bearings of rotary screw compressors typically require more frequent inspection and replacement.

- Repair & maintenance costs. In general, rotary screw compressors are more complex in design and require more maintenance and repair than their rotary vane counterparts.

Featured Rotary Screw Air Compressors

At Energy Machinery, we provide a variety of rotary screw air compressor options to suit specific applications. These include:

- VS Series™ – Variable Speed Rotary Screw Compressors

- VST Series™ – Two-Stage Variable Speed Rotary Screw Compressors

- GD EnviroAire – Oil-Free Variable Speed – Rotary Screw Compressors

- GD Integra – Absolute Integration, Maximum Reliability – Rotary Screw Air Compressors

Rotary Screw Air Compressors from Energy Machinery

Energy Machinery offers an extensive selection of rotary screw air compressors from Gardner Denver and other leading manufacturers. With five decades of experience in our industry, we have the expertise and product selection to meet your specific needs while adhering to your budget.

To learn more about our rotary screw air compressors or other products, please contact us today.