Cycling Refrigerated Air Dryer Vs. Non-Cycling

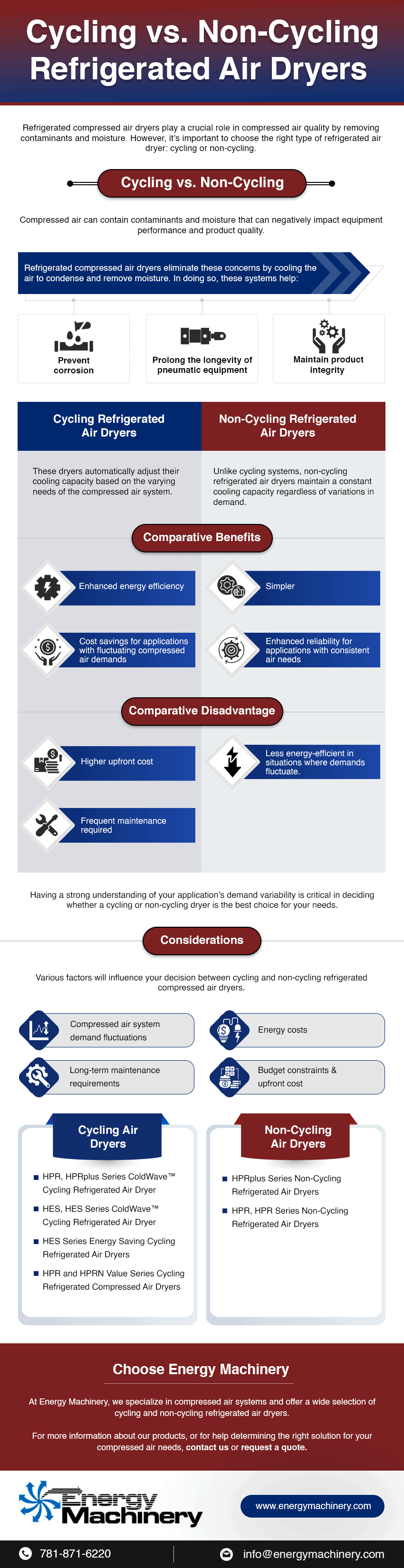

Compressed air is critical in numerous industrial processes, and maintaining its quality is paramount in ensuring optimal system performance. Refrigerated compressed air dryers play a crucial role in compressed air quality by removing contaminants and moisture. However, it’s important to choose the right type of refrigerated air dryer: cycling or non-cycling.

Here, you’ll learn more about cycling and non-cycling refrigerated air dryers, including their unique benefits and characteristics, to help you make the right choice for your application.

Cycling Refrigerated Air Dryer Vs. Non-Cycling: Understanding Compressed Air

Although compressed air is essential for various applications, it can contain contaminants and moisture that can negatively impact equipment performance and product quality. Refrigerated compressed air dryers eliminate these concerns by cooling the air to condense and remove moisture. In doing so, these systems help to prevent corrosion, prolong the longevity of pneumatic equipment, and maintain product integrity.

Depending on the specific application, you may want to use either a cycling refrigerated air dryer or a non-cycling model.

Cycling Refrigerated Air Dryer

Cycling refrigerated air dryers automatically adjust their cooling capacity based on the varying needs of the compressed air system. This level of adaptability results in enhanced energy efficiency and cost savings for applications with fluctuating compressed air demands. However, it’s important to note that these systems often come with higher upfront costs and maintenance requirements compared to non-cycling air dryers.

Non-Cycling Refrigerated Air Dryer

Unlike cycling systems, non-cycling refrigerated air dryers maintain a constant cooling capacity regardless of variations in demand. These air dryers are simpler and offer enhanced reliability for applications with consistent air needs; however, they may be less energy-efficient in situations where demands fluctuate.

Having a strong understanding of your application’s demand variability is critical in deciding whether a cycling or non-cycling dryer is the best choice for your needs.

Considerations for Choosing Cycling Refrigerated Air Dryer Vs. Non-Cycling

Various factors will influence your decision between cycling and non-cycling refrigerated compressed air dryers. To ensure you make the right choice for your unique application, be sure to consider the following:

- Demand fluctuations. If your compressed air system’s demand fluctuates frequently, you may want to opt for a cycling refrigerated air dryer. Conversely, if your demand is constant and rarely changes, a non-cycling model might work better.

- Energy costs. Cycling refrigerated air dryers only refrigerate as needed based on system demand, which will help cut down on energy expenses. If energy costs aren’t a huge concern, you may benefit from the increased reliability of a non-cycling system.

- Long-term maintenance requirements. Maintenance is another key factor to consider. Cycling air dryers have more maintenance requirements, whereas non-cycling air dryers are simpler in design and therefore come with reduced maintenance needs.

- Budget constraints. Due to the higher initial cost of cycling refrigerated compressed air dryers, they may not be the best option if budget is a major concern.

Cycling and Non-Cycling Refrigerated Air Dryers from Energy Machinery

At Energy Machinery, we carry a number of refrigerated compressed air dryers, including both non-cycling and cycling models:

Non-Cycling

Our selection of non-cycling refrigerated air dryers includes:

- HPRplus Series Non-Cycling Refrigerated Air Dryers

- HPR, HPR Series Non-Cycling Refrigerated Air Dryers

Cycling

- HPR, HPRplus Series ColdWave™ Cycling Refrigerated Air Dryer

- HES, HES Series ColdWave™ Cycling Refrigerated Air Dryer

- HES Series Energy Saving Cycling Refrigerated Air Dryers

- HPR and HPRN Value Series Cycling Refrigerated Compressed Air Dryers

Choose Energy Machinery

Based on factors such as demand, energy expenses, maintenance, and initial cost, you can determine which type of refrigerated air dryer is right for your compressed air application. These systems not only help to increase operational efficiency but also ensure product integrity and quality.

At Energy Machinery, we specialize in compressed air systems and offer a wide selection of cycling and non-cycling refrigerated air dryers.

For more information about our products, or for help determining the right solution for your compressed air needs, contact us or request a quote today.