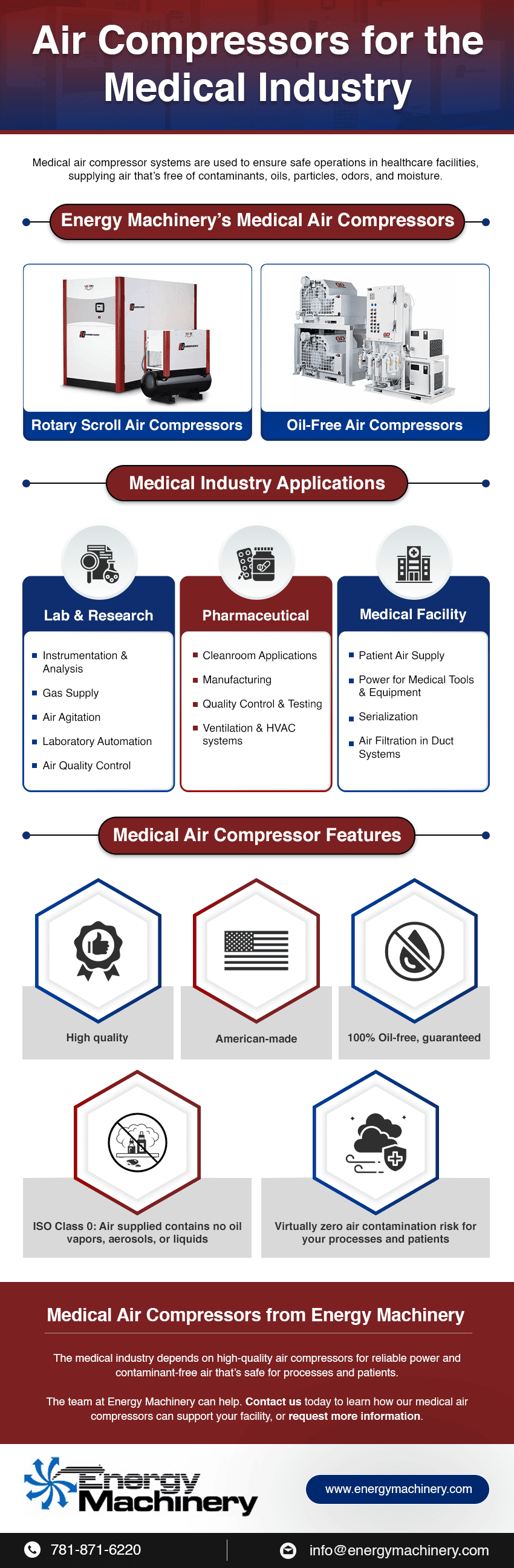

The medical industry uses air compressors for powering critical tools and equipment, facilitating sterilization, and providing pure air to patients. To ensure safe operations, medical air compressor systems for healthcare facilities must supply air that’s free of contaminants, oils, particles, odors, and moisture.

At Energy Machinery, Inc., we have medical air compressors that meet the stringent safety standards of healthcare applications.

Energy Machinery’s Medical Air Compressors

To address the needs of numerous healthcare applications, Energy Machinery supplies medical facilities with multiple varieties of NFPA and CSA code-compliant air compressors, such as:

- Rotary scroll air compressors. We carry rotary scroll air compressors, as well as rotary screw and vane compressors, from Gardner Denver. Backed by five decades of experience, the company’s compressors deliver high performance, reliability, energy savings, and low or high horsepower for periodic or continuous applications.

- Oil-free air compressors. Our Class 0, 100% oil-free air compressors are available in two-stage fixed and variable speed rotary screw varieties. Energy Machinery supplies numerous oil-less air compressor options to meet clients’ varied needs.

Lab/Research Applications

Laboratory-grade air compressors are compatible with a range of applications within medical laboratories and research and development operations. These include:

- Instrumentation and analysis. Air compressors are capable of powering mass spectrometers, gas chromatographs, and various other laboratory instruments by supplying a continuous stream of high-quality air that enables precision measurements for analysis purposes.

- Gas supply. Compressed air equipment can also supply instruments or medical experiments with pure, dry gas. The gas chromatography process, for example, requires carrier gas.

- Air agitation. Laboratories and R&D departments use compressed air to agitate substances, effectively mixing them to carry out biological or chemical processes or research. Not only is this a highly efficient way to mix solutions but it also helps guarantee solution uniformity.

- Laboratory automation. Compressed air can even drive automation. Labs often use pneumatic actuators, robotics, and related automated devices to promote consistency and accuracy when dealing with chemicals and medical samples. Such equipment can use air from medical air compressors to operate.

- Air quality control. Air that contains oils, moisture, or contaminants can compromise medical experiments and damage sensitive equipment. Medical air compressors with filtration and drying capabilities generate the pure, dry air that such applications require.

Pharmaceutical Applications

Air compressors play a critical role in the overall efficiency, quality, and safety of pharmaceutical operations. Examples include:

- Cleanroom applications. Cleanrooms are critical environments for many pharmaceutical processes. They allow pharma companies to protect product integrity and ensure safety. Compressed air has applications in equipment sterilization and aseptic techniques, and it also facilitates control of the room’s environmental conditions.

- Manufacturing. Pharmaceutical manufacturers make use of numerous devices to produce, coat, package, and process medications, many of which can be powered by compressed air. For example, powder-filling equipment and tablet presses as well as pneumatic conveyors and blister packaging machines are common applications for medical air compressors.

- Quality control and testing. Pharmaceutical operations can use compressed air as part of their quality control processes and inspections. Compressed air assists in leak testing and gas chromatography to help testers evaluate drug containers and compounds, respectively.

- Utilities. Ventilation and HVAC systems are examples of general utilities for which pharmaceutical companies can use compressed air. It also has applications in general facility maintenance.

Medical Facility Applications

Within a medical facility, air compressors provide:

- Patient air supply. Clean air is essential for patients under sedation and those having trouble breathing without help. When pressurized, this air aids in operating medical equipment like ventilators.

- Power for medical tools and equipment. Compressed air can provide power for everything from mammogram equipment, x-ray machines, and hospital beds to ventilators, surgical tools, and drills.

- Sterilization. Helping keep medical facilities contaminant-free, air compressors also deliver power for cleaning and sterilizing equipment.

- Air filtration in duct systems. Medical air compressors can supply facility duct systems with filtered air for optimal air purity.

Medical Air Compressor Features

Medical air compressors from Energy Machinery are high-quality, American-made, and 100% oil-free — guaranteed. They’re also ISO Class 0, meaning that the air they supply contains no oil vapors, aerosols, or liquids. Our medical air compressors present virtually zero air contamination risk for your processes and patients.

Medical Air Compressor Services

In addition to equipment solutions, Energy Machinery has been providing reliable air compressor services in New England since 1971. We offer:

- Turnkey installations

- Troubleshooting

- 24-hour field service

- Fast, dependable in-house air compressor rebuilding and repair

- Planned maintenance programs

- Periodic walk-through system evaluations to provide professional advice on use and maintenance

- Entire fleet of electric air compressor rentals to meet the demands of any job (5 to 150 hp)

Medical Air Compressors From Energy Machinery

The medical industry depends on high-quality air compressors for reliable power and contaminant-free air that’s safe for processes and patients. As such, compressed air systems for healthcare facilities often include capabilities for filtration, drying, and monitoring to achieve air of sufficient purity and without excessive moisture. The team at Energy Machinery can help. Contact us today to learn how our medical air compressors can support your facility, or request more information.