Positive displacement blowers, also called rotary blowers, work by pulling air into a rotary chamber and pushing it out in a chosen direction. These blowers are common in manufacturing and processing for tasks like vacuuming, cooling, moisture regulation, and cleaning.

Choosing the right blower is crucial based on specific application needs and energy requirements.

With over 50 years of industry expertise, Energy Machinery, Inc. provides a variety of positive displacement blowers from leading brands, in addition to 24-hour field service. Learn more about positive displacement blowers, the different types available, and the products we carry.

What Is a Positive Displacement Blower?

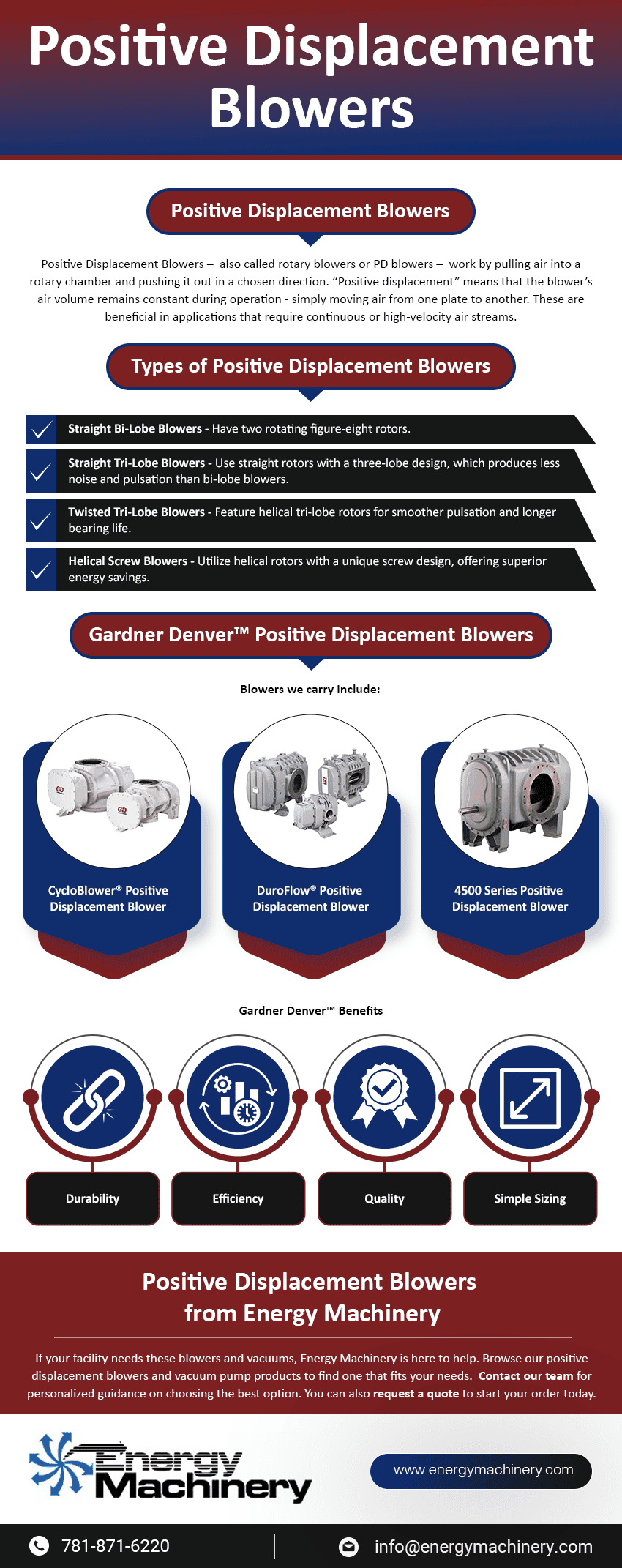

Sometimes called “PD blowers,” positive displacement blowers move air in a range of industries such as agriculture, chemical, and bulk transport. The term “positive displacement” means that the blower’s air volume remains constant during operation, simply moving the air from one place to another.

PD blowers hold a specific amount of air and push it out forcefully via reciprocating pistons or rotary lobes, delivering air to complete the necessary task.

PD blowers are versatile because they can be used for both positive and negative pressure pneumatic conveying applications. Unlike air compressors, which have high-pressure ratios, blowers require only a moderate pressure increase. This distinction means PD blowers are more energy-efficient and affordable to run. They are also particularly beneficial in applications that require continuous or high-velocity air streams.

Air movement is a crucial stage in many manufacturing processes, so positive displacement blowers are an easy-to-install piece of equipment for these applications.

Types of Positive Displacement Blowers

There are different types of positive displacement blowers designed to dry, cool, or move various materials more efficiently:

- Straight Bi-Lobe Blowers: Have two rotating figure-eight rotors.

- Straight Tri-Lobe Blowers: Use straight rotors with a three-lobe design, which produces less noise and pulsation than bi-lobe blowers.

- Twisted Tri-Lobe Blowers: Feature helical tri-lobe rotors for smoother pulsation and longer bearing life.

- Helical Screw Blowers: Utilize helical rotors with a unique screw design, offering superior energy savings.

Gardner Denver™ Positive Displacement Blowers

Energy Machinery carries a variety of blower products from leading brands, including positive displacement blowers from Gardner Denver. Gardner Denver leads the industry by providing a diverse range of technology styles tailored to specific needs. Every Gardner Denver product comes with the following benefits:

- Durability

- Efficiency

- Quality

- Simple sizing

CycloBlower® Positive Displacement Blower

The Gardner Denver CycloBlower® Positive Displacement Blower offers key features that enhance its performance and efficiency:

- Shock-free Compression: The blower delivers shock-free compression and steady, smooth discharge without any sudden releases of air pockets into the line.

- Balanced Compression Cycle: Helical screw rotors produce a balanced compression cycle, optimizing the blower’s overall efficiency.

- Minimized Turbulence: It is designed with contoured inlet and discharge ports to reduce turbulence, improving the overall airflow.

- Compact Design: The CycloBlower® requires only minimal floor space to operate.

Every Gardner Denver CycloBlower® provides consistently high performance thanks to:

- Ongoing investment in personnel training

- Comprehensive quality inspections

- Contactless rotors that eliminate lubrication

- Outboard position of rotor bearings that provide atmospheric venting

- Prevention of lubricant contamination

DuroFlow® Positive Displacement Blower

Gardner Denver’s DuroFlow® Positive Displacement Blowers and vacuum pumps supply clean, oil-free air to numerous industries around the world. Key features of the DuroFlow® include:

- Robust bi-lobe rotor profile to prevent the build-up of ingested material

- Serrated rotor tips to enhance airflow while minimizing power consumption

- Sturdy, single-piece reinforced cast iron cylinder for durability and longevity in challenging operating conditions

- Integral ribs for operation in cooler temperatures

- Advanced air and oil seals for leak-free operation

- Dual Splash Lubrication, coupled with an efficient slinger

- Oversized bearings secure the rotor position and provide robust support to each shaft

- Helical timing gears mounted on shaft splines

4500 Series Positive Displacement Blower

Gardner Denver’s 4500 Series Positive Displacement Blowers offer a range of features and benefits for pneumatic conveying applications:

- Made from high-strength materials

- Bi-lobe impellers made of ductile iron, with one-piece alloy steel shafts

- Advanced case design with more vent areas

- Precision machined cylinder made from a single cast of high tensile iron, externally ribbed to prevent distortion

- Precise timing gears

- Bearings are designed for durability in heavy-duty applications

- Dual Splash Lubrication

- Mechanical seals are available for gas service applications

Positive Displacement Blowers from Energy Machinery

Positive displacement blowers are vital tools used in many industries to perform key processes. If your facility needs these blowers and vacuums, Energy Machinery is here to help. In addition to our comprehensive product line and replacement parts, we offer engineering services like energy audits, leak detection analysis, compressor room analysis, and more.

Browse our positive displacement blowers and vacuum pump products to find one that fits your needs. Contact our team for personalized guidance on choosing the best option. You can also request a quote to start your order today.