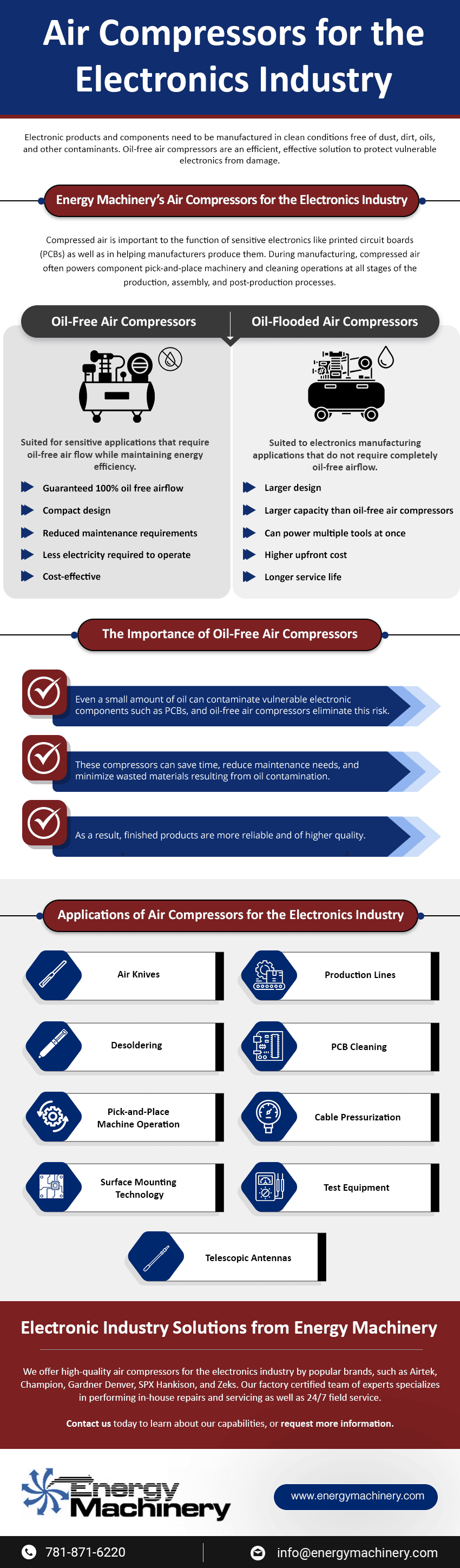

Electronic products and components need to be manufactured in clean conditions free of dust, dirt, oils, and other contaminants. These impurities can trigger short circuits, induce malfunctions, or act as insulators, causing delicate parts to overheat more quickly. Oil-free air compressors are an efficient, effective solution to protect vulnerable electronics from damage.

How Air Compressors Are Used in the Electronics Industry

Compressed air is important to the function of sensitive electronics like printed circuit boards (PCBs) as well as in helping manufacturers produce them. During manufacturing, compressed air often powers component pick-and-place machinery and cleaning operations at all stages of the production, assembly, and post-production processes. Manufacturers prefer air compressors for these applications because of their low-impact, energy-efficient operation.

Energy Machinery Air Compressors for the Electronics Industry

Among the wide range of compressed air products we offer, many are well-suited to the diverse needs of the electronics industry. These systems are highly efficient, reducing the compressor’s impact on costs and meeting stringent ISO Class 0 air quality standards.

The best choice of equipment will depend on your specific application’s requirements. Typically, these air compressors are divided into two main categories: oil-free and oil-lubricated.

Oil-Free Air Compressors

Oil-free air compressors supply completely oil-free compressed airflow. They still use oil but not as a lubricant, so the oil never comes into contact with the compressor and poses no oil contamination risk. This design protects the integrity of sensitive electronics while maintaining energy efficiency. This compressor style provides:

- Guaranteed 100% oil free airflow

- Reduced maintenance requirements

- Compact design

- Requires less electricity to operate

- Cost-effectiveness

Oil-Flooded Air Compressors

Oil-lubricated air compressor systems are suited to electronics manufacturing applications that do not require completely oil-free airflow. Their features include:

- Larger design

- Larger capacity than oil-free air compressors

- Can power multiple tools at once

- Higher upfront cost

- Longer service life

Energy Machinery Air Compressor Services

At Energy Machinery, we offer a wide range of air compressor services to support our customers. These services include:

- 24-hour emergency field service to minimize disruptions to your operations

- In-house air compressor rebuilding and repair services with reliable, rapid turnarounds for most of New England

- Professional consultations and site walkthroughs to evaluate and recommend equipment, configurations, and maintenance needs for your air compressor system

- Scheduled maintenance programs to ensure optimal equipment performance, including preventative maintenance

- Troubleshooting services to identify issues with your air compressor

- Turnkey installations

- Fleet of electric air compressor rentals from 5 to 150 horsepower

Importance of Oil-Free Air Compressors in the Electronics Industry

Most high-performance air compressors are oil-lubricated. These systems use advanced filtration technologies to remove oil from the compressed airflow, but contamination is still possible, especially if the filters encounter unintentional ambient temperature fluctuations. If the temperature rises, filter performance can be compromised, increasing oil carry-over.

Even a small amount of oil can contaminate vulnerable electronic components such as PCBs, but oil-free air compressors eliminate this risk. They can also save time, reduce maintenance needs, and minimize wasted materials and products that result from oil contamination. As a result, finished products are more reliable and higher quality for end users.

Applications of Air Compressors for the Electronics Industry

Air compressors serve in numerous functions and stages of the electronics manufacturing process. Some of these roles include:

- Air knives in the production of electronics

- Production lines

- Desoldering

- Printed circuit board (PCB) cleaning

- Pick-and-place machine operation

- Cable pressurization

- Surface mounting technology

- Test equipment

- Telescopic antennas

Air Compressors for the Electronics Industry from Energy Machinery

At Energy Machinery, we have decades of experience supporting our customers with consultation, maintenance, technical support, and air compressor purchases, rentals, and services. We offer high-quality air compressors for the electronics industry by popular brands, such as Airtek, Champion, Gardner Denver, SPX Hankison, and Zeks. Our factory certified team of experts specializes in performing in-house repairs and servicing as well as 24/7 field service.

Contact us today to learn more about our full capabilities, or request a quote for your air compressor needs.