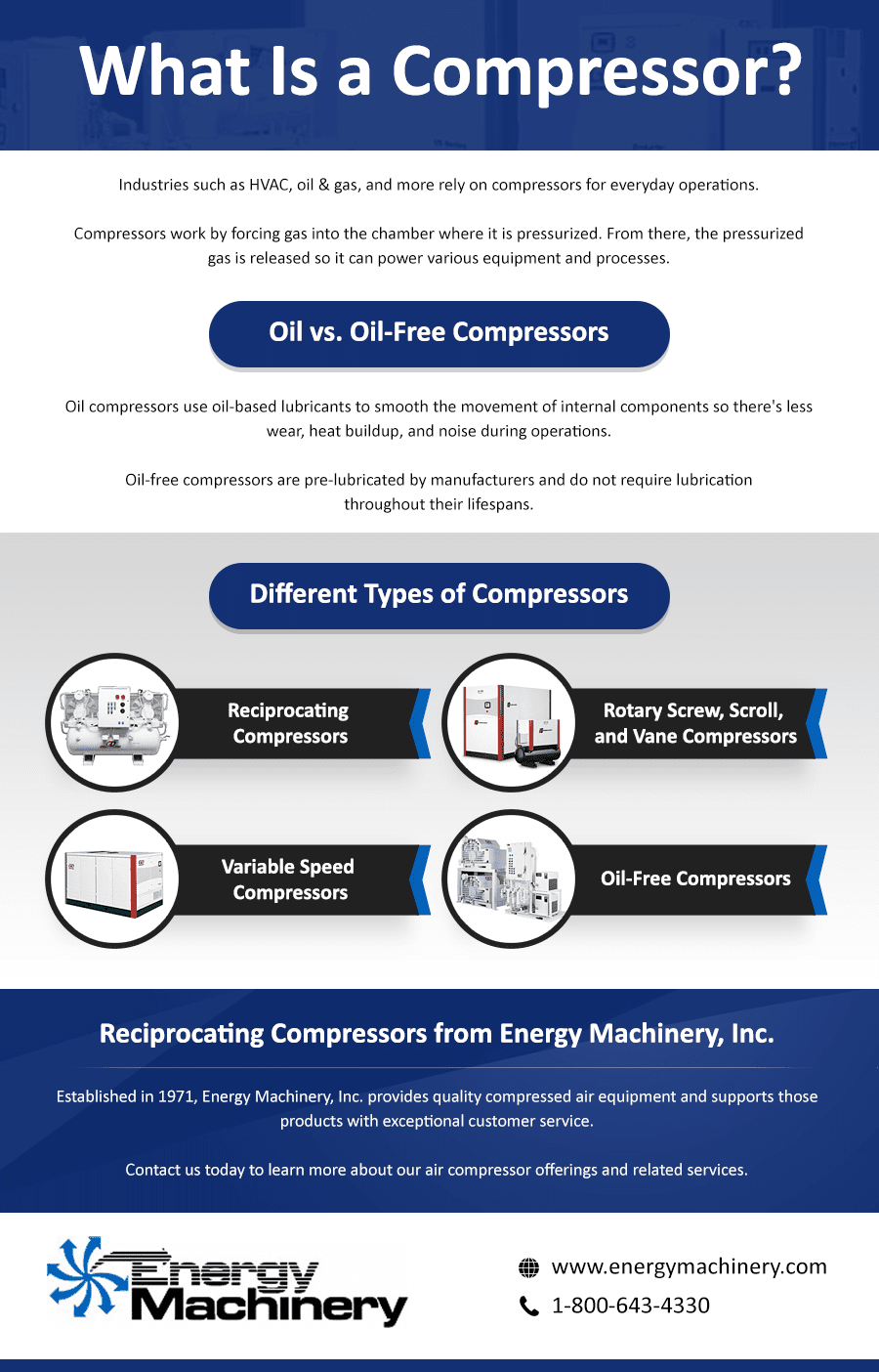

What Is a Compressor?

Many industrial processes rely on compressors to increase the pressure of a gas by reducing its volume. Industries such as HVAC, oil & gas, and more rely on compressors for everyday operations. Compressors work by forcing gas into the chamber where it is pressurized. From there, the pressurized gas is released so it can power various equipment and processes. Here, we will discuss the differences between oil and oil-free compressors as well as the various types of compressors available at Energy Machinery, Inc.

Oil vs. Oil-Free Compressors

Oil and oil-free gas compressors both deliver compressed, high-pressure gases that can be used in a wide variety of pneumatic applications. However, there are several key differences between these two categories. Oil compressors use oil-based lubricants to smooth the movement of internal components so there’s less wear, heat buildup, and noise during operations. Oil-free compressors are pre-lubricated by manufacturers and do not require lubrication throughout their lifespans.

Other important differences include:

- Maintenance Requirements. Oil compressors require routine maintenance and frequent oil changes, whereas oil-free compressors are maintenance-free.

- Lifespan. Oil compressors last longer than oil-free alternatives (provided they have proper maintenance). They are more rugged, more durable, and less likely to break down due to wear and heat buildup.

- Mobility. Oil-free compressors are lighter and more portable, whereas oil compressors are heavier and not as mobile.

- Price. Oil-free compressors are cheaper per unit than oil compressors. They are also cheaper due to not needing frequent applications of oil lubricant. However, the increased lifespan of oil compressors can lead to overall savings depending on how often the unit is used.

Different Types of Compressors

There are many different types of compressors to suit the needs of various industries and applications. At Energy Machinery, Inc., we offer the following compressor types:

- Reciprocating Compressors:

- Reciprocating compressors, or piston compressors, are positive displacement machines that rely on the reciprocating action of two or more pistons to compress gas and deliver it at high pressure. The gas is compressed within a cylinder and discharged through valves into receiving tanks. Common applications for reciprocating compressors include gas transmission pipelines, refineries, and more.

- Rotary Screw, Scroll, and Vane Compressors:

- Rotary screw compressors use two meshed rotors to pull in gas. The gas is then compressed as it moves down through the rotors before it is discharged through a discharge port. This type of compressor offers quiet operation compared to reciprocating compressors and is ideal for construction and road building applications.Scroll compressors feature orbiting and stationary spirals which work to decrease the volume of space between them as the orbiting spirals move along the path of the stationary spirals. The gas enters at the outer edge of the scrolls and discharge takes place near the center. This type of compressor is commonly used for home air-conditioning and low-end applications.Vane compressors rely on a series of vanes that rotate from the suction side to the discharge side of an eccentric cavity. As the vanes sweep along the wall, they reduce the volume of space, compressing the gas trapped within. These compressors are commonly used in oil & gas and other process industries.

- Variable Speed Compressors:

- These units are rotary screw air compressors with variable speed drives that control the motion of the pieces. This type of compressor is very energy-efficient and can change to meet the needs of fluctuating demands.

- Oil-Free Compressors:

- Oil-free compressors do not rely on lubricating oil, making them ideal for applications where contamination is a concern, such as food processing, pharmaceuticals, and more. We offer a range of oil-free compressors, including rotary screw and two stage variable speed centrifugal variations.

Providing Quality Air Compressors to New England

Compressors are available in many types to suit the requirements of various industries and applications. Since 1971, Energy Machinery, Inc. has provided high-quality compressed air equipment to our customers. To learn more about our products, or for help selecting the best compressor option for your needs, contact us today.