All About Medical Air Compressors

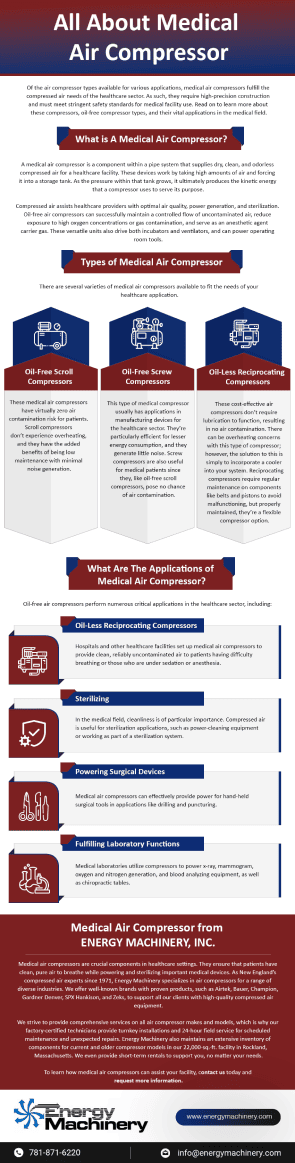

Of the air compressor types available for various applications, medical air compressors fulfill the compressed air needs of the healthcare sector. As such, they require high-precision construction and must meet stringent safety standards for medical facility use. Read on to learn more about these compressors, oil-free compressor types, and their vital applications in the medical field.

What Is a Medical Air Compressor?

A medical air compressor is a component within a pipe system that supplies dry, clean, and odorless compressed air for a healthcare facility. These devices work by taking high amounts of air and forcing it into a storage tank. As the pressure within that tank grows, it ultimately produces the kinetic energy that a compressor uses to serve its purpose.

Compressed air assists healthcare providers with optimal air quality, power generation, and sterilization. Oil-free air compressors can successfully maintain a controlled flow of uncontaminated air, reduce exposure to high oxygen concentrations or gas contamination, and serve as an anesthetic agent carrier gas. These versatile units also drive both incubators and ventilators, and can power operating room tools.

Types of Medical Air Compressors

There are several varieties of medical oil-free air compressors available to fit the needs of your healthcare application.

Oil-Free Scroll Compressors

These medical air compressors have virtually zero air contamination risk for patients. Scroll compressors don’t experience overheating, and they have the added benefits of being low maintenance with minimal noise generation.

Oil-Free Screw Compressors

This type of medical compressor usually has applications in manufacturing devices for the healthcare sector. They’re particularly efficient for lesser energy consumption, and they generate little noise. Screw compressors are also useful for medical patients since they, like oil-free scroll compressors, pose no chance of air contamination.

Oil-Less Reciprocating Compressors

These cost-effective air compressors don’t require lubrication to function, resulting in no air contamination. There can be overheating concerns with this type of compressor; however, the solution to this is simply to incorporate a cooler into your system. Reciprocating compressors require regular maintenance on components like belts and pistons to avoid malfunctioning, but properly maintained, they’re a flexible compressor option.

What Are the Applications of Medical Air Compressors?

Oil-free air compressors perform numerous critical applications in the healthcare sector, including:

- Assisting patients in breathing. Hospitals and other healthcare facilities set up medical air compressors to provide clean, reliably uncontaminated air to patients having difficulty breathing or those who are under sedation or anesthesia.

- Sterilizing. In the medical field, cleanliness is of particular importance. Compressed air is useful for sterilization applications, such as power-cleaning equipment or working as part of a sterilization system.

- Powering surgical devices. Medical air compressors can effectively provide power for hand-held surgical tools in applications like drilling and puncturing.

- Fulfilling laboratory functions. Medical laboratories utilize compressors to power x-ray, mammogram, oxygen and nitrogen generation, and blood analyzing equipment, as well as chiropractic tables.

Medical Air Compressors From Energy Machinery, Inc.

Medical air compressors are crucial components in healthcare and pharmaceutical settings. They ensure that patients have clean, pure air to breathe while powering and sterilizing important medical devices. As New England’s compressed air experts since 1971, Energy Machinery specializes in air compressors for a range of diverse industries. We offer well-known brands with proven products, such as Airtek, Bauer, Champion, Gardner Denver, SPX Hankison, and Zeks, to support all our clients with high-quality compressed air equipment.

We strive to provide comprehensive services on all air compressor makes and models, which is why our factory-certified technicians provide turnkey installations and 24-hour field service for scheduled maintenance and unexpected repairs. Energy Machinery also maintains an extensive inventory of components for current and older compressor models in our 22,000-sq.-ft. facility in Rockland, Massachusetts. We even provide short-term rentals to support you, no matter your needs.

To learn how medical air compressors can assist your facility, contact us today and request more information.