Compressed air plays an important role in the healthcare industry, powering medical equipment and providing contamination-free air that helps maintain sterile environments. Due to their clean operation, oil-free compressors are the preferred choice for medical environments. Energy Machinery offers an extensive range of oil-free, high-performance medical air compressors tailored to hospital, lab, and pharmaceutical manufacturing needs.

Our equipment ensures safe operations and reliable access to contaminant-free air. In this comprehensive guide, you will learn more about different types of medical air compressors, their specifications, and our services.

What Is a Medical Air Compressor?

Medical air compressors generate dry, clean, and oil-free compressed air for healthcare applications. They are used with many types of medical devices, as well as during surgeries, treatments, lab processes, pharmaceutical production, and patient care tasks. Unlike industrial oil-flooded air compressors, oil-free compressors deliver air that meets strict standards for cleanliness, dryness, and purity. Medical air compressors also meet precision pressure and flow requirements for safe operation.

CORE REQUIREMENTS

The critical features and functions of medical air compressors are related to cleanliness, industry compliance, and operational characteristics. Medical grade air compressors must:

Medical Air Compressor Types

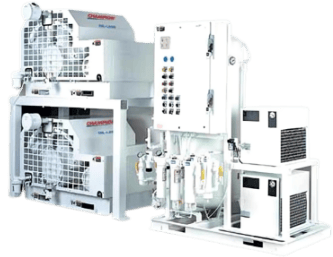

There are several types of air compressor configurations suitable for medical applications. These include rotary screw, scroll, and vane compressors. These particular designs create minimal noise, are highly energy efficient, and can run continuously without creating vibrations. Each type of air compressor has different features and capabilities that make it more or less appropriate for different applications. From light-demand to heavy-duty continuous use, there is an option for every need.

Learn more about the types of air compressors for medical use in the chart below.

| Compressor Type | Description | Best For |

|---|---|---|

| Rotary Scroll | Compact, oil-free, continuous duty | Labs, dental, surgical suites |

| Rotary Screw | Efficient, durable, variable-speed options | Hospitals, central air systems |

| Rotary Vane | Simple and rugged with long service life | Light-to-moderate demand |

| Two-Stage Oil-Free | High-output with zero oil contamination | Large hospitals, pharma plants |

MEDICAL AIR COMPRESSOR SPECIFICATION GUIDE

There are a number of established performance specifications for medical air compressors. To ensure patient safety, these machines must meet defined standards for air purity, dew point, carbon monoxide levels, and more. They must also comply with NFPA 99, a healthcare facilities code that sets requirements for medical air systems and medical instrumentation air systems.

At Energy Machinery, our solutions for the medical industry deliver proven performance. Not only are they 100% American-made and oil-free, but they’re also ISO Class 0-certified, which ensures air is free from vapors, liquids, and aerosols. In addition, they incorporate necessary safety features like backflow prevention systems, which prevent compressed air from flowing back into the compressor and contaminating the air supply with bacteria, moisture, or other contaminants.

Medical air compressors have features that are important in areas like patient rooms, critical care spaces, operating rooms, and other care settings, such as:

- ISO Class 0 certification for air purity

- Built-in refrigeration dryer and filtration stages

- 5 to 150 hp capacity options, with custom configurations also available

- Available Built-in refrigeration Dryer and filtration stages

- Noise level ratings (dBA) for sensitive environments

- Alarm systems and remote monitoring capabilities

- NFPA 99 compliance

Compressed air systems that are not properly specified for medical use are non-compliant and can pose danger to patient health. Using the wrong system for a given application can result in frequent maintenance and unplanned downtime as well as exposure to contaminants or even carbon monoxide poisoning.

There are many air compressor designs, sizes, and performance capabilities available, and it’s important to understand your needs and options carefully.

HOW TO SIZE A MEDICAL AIR COMPRESSOR

Determining the appropriate air compressor size for an application depends on where, when, and how it will be used with different devices. The most important considerations include:

Correctly sizing a medical air compressor requires familiarity with the application as well as the capabilities and limits of different models. To ensure full code compliance and proper sizing, partner with an experienced provider like Energy Machinery. Request a quote today to get started.

Request a QuoteAPPLICATIONS FOR MEDICAL AIR COMPRESSORS

Medical air compressors can be used in a variety of healthcare settings to power medical tools and instruments, provide cleanroom pressurization, drive pneumatic lab automation equipment, and more.

At Energy Machinery, we’ve helped medical industry customers from many different fields and settings select the optimal compressed air solution for their needs. Some of the most common applications for our products are highlighted below.

Hospitals and clinical environments require oil-free air compressors for surgical tools, anesthesia machines, and patient support systems, like adjustable beds. They are also used with air filtration and equipment sterilization tools.

Air compressors are used to pressurize cleanroom environments and are also essential for HVAC equipment in pharmaceutical manufacturing facilities. Air compressors also provide pneumatic control for tablet presses, filling, and blister packaging equipment. They also play an important role in powering quality control instruments, like leak testing equipment.

Laboratory and R&D environments often use air compressors for chromatography and spectrometry operations, as well as for pneumatic lab automation tasks. In addition, many solution mixing tasks require compressed air to agitate and combine substances.

Energy Machinery provides comprehensive medical air compressor services, from convenient equipment rentals to preventative maintenance, 24-hour emergency services, and in-house repairs. Our service offerings include:

- Turnkey installation and startup

- Preventive maintenance programs

- 24-hour emergency service

- In-house repair and rebuilding

- Large fleet of rental compressors, from 5 to 150 hp

- Periodic walk-through evaluations

Read More: What to Look for in an Air Compressor Service Provider

As compressed air experts, the team at Energy Machinery has been serving the medical industry for over 50 years. Below are some of the many reasons why our customers trust us for their compressed air needs.

- Authorized distributor of Gardner Denver and other top brands

- Trusted by healthcare and life science providers across New England

- Proven track record of reliability and customer support

- ISO Class 0-certified solutions and NFPA-compliant systems

GET MEDICAL-GRADE AIR YOU CAN TRUST

The medical industry has complex requirements for compressed air performance and quality. At Energy Machinery, we meet these needs with an extensive product selection, industry-leading expertise, and unrivaled customer care. We’ve partnered with over 20 major manufacturers to bring customers a range of compressed air equipment options for nearly any application.

Contact Energy Machinery to discuss your medical compressed air requirements.

Call us at: 1-800-643-4330

Serving: Massachusetts, New Hampshire, Rhode Island, Connecticut, Vermont, Maine